Wholesale businesses run on tight schedules, big order volumes, and complex supply chains. When you’re managing thousands of SKUs, multiple warehouses, bulk orders, and fast turnaround times, even a small mistake can snowball into delays, losses, or angry customers. And in a world where businesses are scaling faster than ever, traditional spreadsheets or manual logs just can’t keep up.

That’s exactly where a wholesale inventory management system makes all the difference. It gives wholesale distributors real-time visibility, automation, and control across stock, sales, and supply chain operations, and everything you need to run efficiently and keep customers happy.

This guide breaks down what a wholesale inventory management system does, why it matters, and how it helps you streamline your operations from end to end.

What Is a Wholesale Inventory Management System?

A wholesale inventory management system is a digital platform that helps businesses track stock, manage sales orders, automate purchasing, control warehouses, and streamline the entire supply chain. Instead of juggling multiple tools or relying on manual records, wholesalers get everything in one connected system.

It’s designed for:

Unlike retail systems, wholesale inventory tools are designed to handle large order sizes, multiple pricing tiers, bulk discounts, and multi-warehouse operations simultaneously.

Why Wholesale Businesses Need Inventory Automation

Wholesale businesses handle large numbers of products and restock often. When inventory is managed manually, small errors can quickly turn into stockouts, overstocking, or delayed orders. Without real-time visibility across warehouses, it becomes hard to know what’s available and where, which slows down daily operations.

Today, many wholesalers sell through multiple channels and serve B2B customers who expect fast and accurate deliveries. To meet these expectations, stock levels must stay updated everywhere at all times. With supply chain disruptions and changing demand, an inventory management system helps wholesalers stay organized, reduce mistakes, and fulfill orders on time.

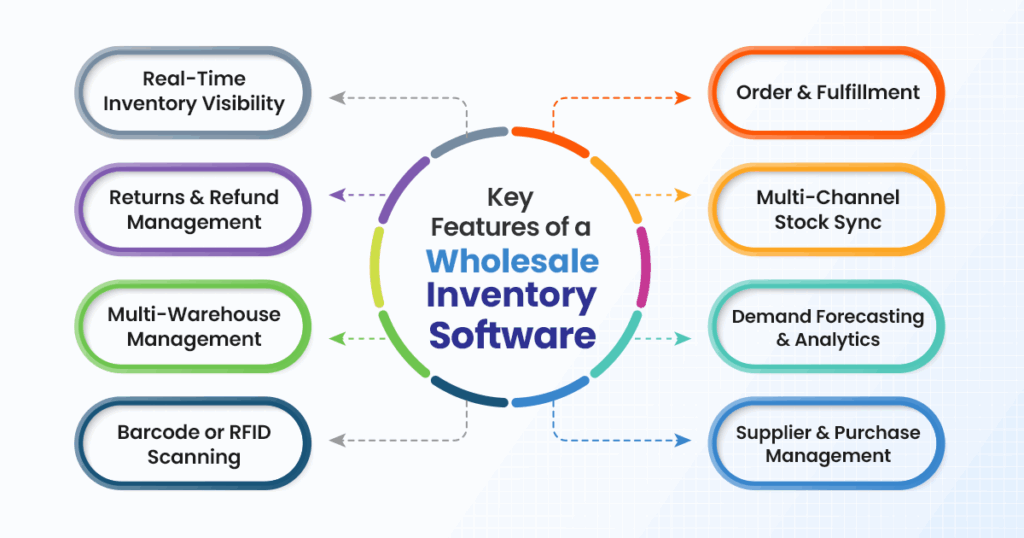

Key Features of an Effective Wholesale Inventory Management System

A reliable wholesale inventory management system is built to handle large volumes, fast-moving stock, and complex operations. The right features help wholesalers reduce errors, save time, and keep inventory, sales, and supply chains perfectly aligned. Below are the most important features to look for.

1. Real-Time Inventory Visibility

Real-time inventory visibility gives you full control over your stock at all times. Every movement is recorded instantly, so you always know what is available, where it is stored, and how fast it is selling. This helps you avoid surprises and make quicker, smarter decisions.

You benefit from:

- Live-stock updates across all locations

- Clear warehouse-wise inventory visibility

- More accurate and faster order fulfillment

- No guesswork or manual checking

2. Automated Reordering

Running out of stock can stop sales and damage customer trust. Automated reordering ensures you restock at the right time without manual follow-ups or delays. The system handles purchasing in the background so you can focus on growth.

Key capabilities include:

- Low-stock alerts before items run out

- Auto-generated purchase orders

- Replenishment based on demand forecasts

- Adjustments based on supplier lead times

3. Multi-Warehouse Management

Many wholesalers operate from more than one warehouse, which makes inventory tracking more complex. A multi-warehouse feature gives you one central view of all locations, helping you move stock efficiently and reduce delays.

With this feature, you can:

- View stock levels across all warehouses

- Transfer inventory between locations easily

- Track warehouse performance individually

- Reduce stock imbalances and delivery delays

4. Barcode or RFID Scanning

Wholesale operations involve handling large quantities of inventory every day. Barcode or RFID scanning speeds up these processes and reduces manual mistakes, making inventory handling faster and more accurate.

This feature helps with:

- Faster receiving of incoming stock

- Quick and accurate picking and packing

- Reduced human errors during handling

- Instant stock updates in the system

5. Order & Fulfillment Management

Wholesale order fulfillment can be complex due to bulk quantities and different customer types. A good system simplifies the entire process by organizing orders and guiding teams through each step.

You can easily manage:

- Bulk and high-volume orders

- Both B2B and B2C sales orders

- Pick, pack, and ship workflows

- Backorders and partial shipments

6. Multi-Channel Stock Sync

Many wholesalers sell through websites, marketplaces, and offline channels at the same time. Multi-channel syncing ensures stock levels stay updated everywhere in real time, no matter where a sale happens.

This helps prevent:

- Overselling across channels

- Stock mismatches between platforms

- Duplicate data entry and manual updates

If you want to understand how multi-channel selling works and why synced inventory is critical, this guide on multi-channel selling and inventory management explains it in detail

7. Demand Forecasting & Analytics

Forecasting allows you to plan inventory based on data instead of guesswork. With clear analytics, you can understand demand trends and prepare for future sales more confidently.

You gain insights into:

This leads to smarter purchasing and healthier cash flow.

8. Supplier & Purchase Management

Strong supplier management keeps your inventory moving without delays. A wholesale inventory system helps you organize supplier data and monitor purchasing activities in one place.

You can:

- Track supplier performance

- Record and analyze lead times

- Manage communication more clearly

- Monitor purchase order status

This reduces delays and unexpected stock shortages.

9. Pricing & Discount Control

Wholesale pricing is often complex, with different rates for different customers. A good system makes pricing easier to manage without manual adjustments or errors.

It supports:

- Tier-based pricing

- Bulk discounts

- Contract or customer-specific pricing

- Consistent pricing across all channels

10. Returns & Refund Management

Returns are a normal part of wholesale operations, and managing them properly keeps inventory accurate. A structured returns process helps track items and decide what can be restocked.

The system helps you track:

- Returned inventory

- Damaged or defective goods

- Items eligible for restocking or replacement

This keeps your inventory clean, updated, and reliable.

Major Challenges Wholesalers Face Without a System

When wholesalers depend on manual processes or outdated tools, common problems include:

- Inaccurate stock counts due to manual data entry

- Slow replenishment because there’s no real-time visibility

- Overstocking caused by poor forecasting

- Communication gaps with suppliers are leading to delays

- Lost or misplaced inventory across warehouses

- Slow order fulfillment

- Difficulty scaling because systems can’t keep up

- No proper insights to guide decisions

These issues cost time, money, and customer trust and they’re exactly what a wholesale inventory system is designed to fix.

How a Wholesale Inventory Management System Streamlines Stock Handling

In 2026, managing wholesale inventory is no longer about spreadsheets or manual counting. Modern inventory systems use automation and real-time data to keep stock, sales, and supply chain activities connected from start to finish. This means fewer mistakes, faster order processing, and better control over your inventory.

Let’s break down how a wholesale inventory management system makes stock handling easier.

1. Essential Features That Simplify Stock Management

- Real-Time Inventory Tracking

Stock levels update instantly every time a product is sold, received, or moved. This helps prevent overselling and gives you a clear view of inventory across all warehouses at any moment.

- Automated Reorder Alerts

You can set minimum stock levels for each product. When stock runs low, the system sends alerts or automatically creates purchase orders so you never run out unexpectedly.

- Barcode or RFID Scanning

Scanning products during receiving, picking, and audits speeds up work and reduces human errors. This improves inventory accuracy and saves valuable time for your team.

- Inventory Categorization (ABC Analysis)

Products are grouped based on value and sales movement. This helps you focus more on high-value or fast-selling items that have the biggest impact on your revenue.

2. Improving Sales and Order Processing Workflows

- Self-Service B2B Ordering Portals

Wholesale customers can place orders, check prices, and track shipments on their own. This reduces back-and-forth communication and speeds up the ordering process.

- Multi-Channel Inventory Syncing

Your inventory stays updated across all sales channels, including online stores, marketplaces, and POS systems. This keeps stock numbers accurate everywhere and avoids overselling.

- Flexible Pricing and Product Bundles

The system can handle bulk pricing, discounts, and bundled products automatically. This removes the need for manual calculations and reduces pricing mistakes.

- Smarter Demand Forecasting

The system uses past sales data and trends to predict future demand. This helps you stock the right amount of products at the right time.

- Better Supplier Management

You can track supplier performance, including delivery time and pricing accuracy. This helps you choose reliable suppliers and negotiate better deals.

- Optimized Shipping and Delivery

Inventory systems can connect with shipping tools to plan faster and more cost-effective delivery routes, reducing delays and shipping costs.

- 3PL Integration for Growing Businesses

If you use third-party warehouses or fulfillment services, the system keeps everything synced in real time so you always know where your stock is.

Key Benefits of Using a Wholesale Inventory Management System

Managing wholesale inventory can be overwhelming without the right tools. A good inventory system does more than just track stock — it streamlines operations, reduces errors, and helps your business grow. Here’s how wholesalers benefit the most:

- Accurate Stock Data – Know exactly how much inventory you have at any moment to prevent stockouts, overselling, and confusion across warehouses and channels.

- Faster Order Fulfillment – Automated tracking and organized workflows let your team process and ship orders quickly, keeping customers happy.

- Reduced Waste and Overstocking – Keep only what you need, avoid tying up cash in excess stock, and reduce storage costs and product damage.

- Lower Operational Costs – Automation reduces manual work, minimizes errors, and boosts productivity so your team can focus on growth.

- Stronger Supplier Relationships – Track supplier performance, monitor lead times, and communicate efficiently for better partnerships.

- Improved Customer Satisfaction – Accurate stock and timely delivery ensure customers get what they want, building loyalty and repeat business.

- Better Cash Flow Control – Smarter stock management frees up cash tied in excess inventory for budgeting and business growth.

- Scalable Operations – The system adapts easily as your business expands across multiple warehouses, channels, and products.

- Real-Time Analytics for Smarter Decisions – Gain insights into trends, slow-moving items, and sales patterns to optimize stock and improve profitability.

- Streamlined Operations Across the Board – Let your inventory system handle the heavy lifting so procurement, sales, and shipping flow smoothly.

How to Choose the Right Wholesale Inventory Management System

Picking the right inventory software for your wholesale business can feel overwhelming — there are so many options out there! But choosing wisely can save you time, reduce mistakes, and help your business grow smoothly. Here’s what to consider when making your choice:

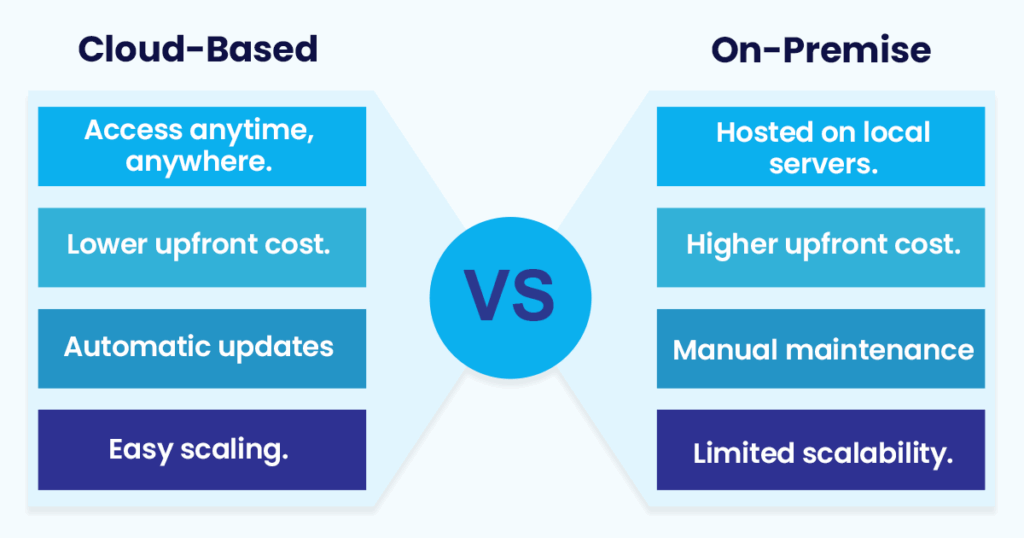

- Cloud-Based vs. On-Premise

Cloud-based systems let you access your inventory from anywhere, anytime, which is perfect if you manage multiple warehouses or remote teams. On-premise systems can give more control, but require IT support and maintenance. Think about what works best for your team and workflow.

- Ease of Use for Your Team

A system is only as good as how well your team can use it. Look for intuitive interfaces, clear dashboards, and minimal training requirements. If your staff struggles with complicated software, mistakes happen, and adoption slows down.

- Integration with eCommerce, ERP, or Accounting Tools

Your inventory system should connect seamlessly with your online stores, ERP, and accounting software. This prevents double entries, keeps your data accurate, and saves hours of manual work every week.

- Automation Capabilities

Automation is a game-changer. Features like automated reorder alerts, batch tracking, and purchase order generation reduce repetitive tasks and human error, giving you more time to focus on growing your business.

- Multi-Warehouse Compatibility

If you manage multiple locations, your system should handle stock transfers, location-specific reports, and real-time updates. This keeps everything synced and avoids surprises like overstock or stockouts.

- Mobile App Support

Mobile access means your team can check stock, scan items, and update orders on the go. This is especially useful for warehouse managers, sales teams, and busy staff who need real-time information anywhere.

- Customer Support Quality

Even the best software can have hiccups. Choose a provider known for quick, helpful support and training resources. A responsive support team saves stress and downtime when issues arise.

- Customization and Scalability

Your business will grow, and your inventory software should grow with it. Look for flexible features that can adapt to new products, sales channels, or warehouse locations without needing to switch systems.

- Total Cost (Including Hidden Fees)

Compare not just the upfront cost, but also subscription fees, add-ons, and implementation charges. A slightly higher-priced system with all-in-one features may actually save more money in the long run.

- Growth-Friendly Features

Finally, make sure the software helps you plan for the future. Features like analytics, reporting, and forecasting aren’t just nice-to-have — they let you scale smartly and avoid costly mistakes as your business expands.

Step-by-Step Guide to Implementing the System

Implementing a new inventory system might sound complicated, but if you follow a clear plan, it can be smooth and stress-free. Here’s a simple roadmap to get you started:

- Audit Your Current Operations

Start by looking at how your inventory works right now. Identify delays, bottlenecks, errors, or inefficiencies. Knowing exactly where things go wrong helps you fix them faster.

- Define Your Pain Points

Pinpoint the areas that need the most improvement. Is it tracking stock across warehouses? Handling bulk orders? Or maybe managing returns? This makes it easier to choose the right software features.

- Choose the Right System

Pick a solution that fits your team’s workflow. Look for ease of use, speed, integration with your existing tools, and automation options that reduce repetitive tasks.

- Map Your Workflows

Understand how inventory moves through your business from procurement to production, storage, and finally shipping. This helps you set up the system in a way that matches your real operations.

- Migrate Your Data

Clean up your spreadsheets and old records, then import them into your new system. Accurate data ensures smooth operations from day one.

- Train Your Team

Make sure everyone knows how to use the system confidently. Provide step-by-step training and resources so mistakes are minimized and adoption is fast.

- Set Up Automations

Configure key automations like reorder alerts, low-stock notifications, batch tracking, and workflow approvals. This reduces manual work and prevents costly errors.

- Track Performance

Monitor key metrics like stock accuracy, order fulfillment speed, and inventory turnover. Use these insights to tweak your system and improve your processes over time.

Streamline Your Wholesale Operations with FullStro

Running a wholesale business comes with a lot of moving parts, from managing stock across warehouses to keeping orders flowing smoothly. FullStro makes it simple. With features like real-time inventory tracking, automated reorder alerts, multi-channel syncing, and smart analytics, FullStro ensures your stock, sales, and supply chain are always in sync.

It reduces manual work, prevents mistakes, and gives you a clear view of your business at a glance. Whether you’re handling B2B orders, managing suppliers, or planning shipments, FullStro helps you save time, cut costs, and keep your customers happy — all while making scaling your business much easier.

Best Practices for Wholesale Inventory Management

To get the most out of your system, follow these best practices:

- Use ABC analysis to identify your most valuable items

- Keep product data updated

- Run cycle counts regularly

- Maintain safety stock intelligently

- Automate repetitive tasks

- Keep your warehouse clean and structured

- Strengthen communication with suppliers

- Standardize receiving and picking processes

- Align stock levels with accurate demand forecasts

Conclusion

A wholesale inventory management system is not just another tool — it’s the backbone of a modern wholesale business. It helps you track stock accurately, fulfill orders faster, streamline your supply chain, and scale without stress. With automation, real-time visibility, and smarter forecasting, your business becomes more efficient, more profitable, and far more resilient.

If you want to stay competitive in today’s fast-moving wholesale market, upgrading to a modern inventory management system is one of the smartest decisions you can make.