If you run a manufacturing business, you already know one simple truth: production can only run smoothly when your inventory does. When materials arrive late, when raw stock runs out, or when finished goods pile up with no tracking — everything gets messy. Customers wait longer, costs rise, and your team feels lost.

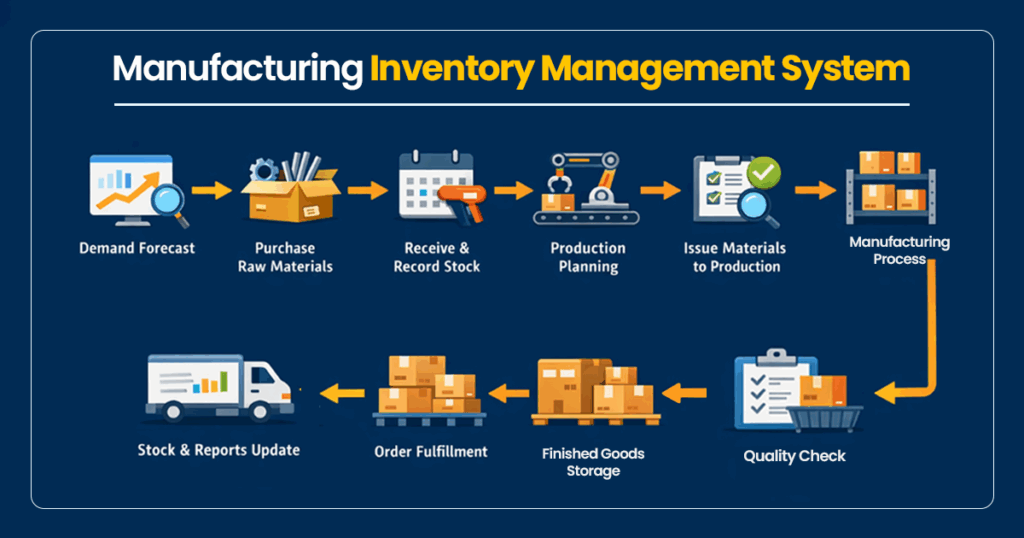

That’s where a strong manufacturing inventory management system comes in. It brings visibility, control, and harmony to your entire production workflow. This guide will walk you through everything you need to know, in a simple and friendly way, so you can make better decisions and improve your output without stress.

Let’s get started.

What is the Manufacturing Inventory Management System?

Manufacturing inventory management isn’t just about counting materials or updating spreadsheets. It’s the backbone of efficient production. A good system helps you know what you have, what you need, and how fast you’re moving.

A manufacturing inventory management system is a software tool that helps you track, manage, and control all inventory used in production. It gives you visibility into what you have, what you need, what’s running low, and what’s stuck on the production floor.

It’s not just a stock tracking tool. It’s the heart of your production process.

Unlike basic inventory software, a manufacturing-focused system understands:

- Production stages

- Material requirements

- Work-in-progress

- Batch tracking

- BOM (Bill of Materials)

- Multi-step workflows

Also, a good manufacturing-focused system helps you:

- Track raw materials in real time

- Monitor work in progress

- Manage finished goods

- Plan production better

- Reduce waste and extra costs

- Avoid stockouts and overstocking

Today, most manufacturers are shifting from manual methods to digital systems because automation reduces errors, speeds up workflows, and improves production quality. In this guide, you’ll learn what a manufacturing inventory system is, why it matters, how it works, and how you can use it to build a more efficient and profitable business.

Why Manufacturing Inventory Management Matters

A manufacturing inventory management system is important because it keeps your entire production line running smoothly. When you always know what materials you have, what you’re running out of, and what stage your products are in, you can avoid costly delays. Without a proper system, factories often deal with missing raw materials, production stoppages, excess stock, and errors that lead to waste.

A good inventory system gives manufacturers real-time visibility and control, which means you can produce consistently, reduce mistakes, save money, and meet customer demand without stress. It helps every part of your operation from procurement to warehouse to production to delivery staying aligned and efficient. In short, it helps you build better products, speed up output, and keep your business competitive in a fast-moving industry.

Essential Types of Manufacturing Inventory

Manufacturing inventory isn’t just one thing. It includes several types, and each one plays a role in your production flow.

1. Raw Materials

These are the basic items you need to begin production. When you track raw materials properly, you avoid sudden shortages that can stop your entire operation. Examples: fabric, metal sheets, chemicals, wood.

2. Work in Progress (WIP)

These are items currently moving through your production line but are not finished yet. Monitoring WIP helps you understand production speed and identify bottlenecks before they become big problems. Examples: partially assembled products, cut fabrics, half-made components.

3. Finished Goods

These are the completed products ready to pack, store, or ship. Keeping a healthy amount of finished goods means you can fulfil customer orders on time without scrambling.

4. MRO (Maintenance, Repair, and Operating Supplies)

These aren’t part of the final product, but your machines and facilities need them to keep running smoothly. Tracking MRO prevents unexpected downtime and costly breakdowns. Examples: lubricants, spare machine parts, cleaning supplies.

For manufacturers dealing with short shelf-life materials, proper tracking is even more critical, these inventory control tips for perishable goods explain how to reduce spoilage and avoid unnecessary losses.

Common Manufacturing Inventory Challenges

- Stockouts — Production stops when materials run out, causing delays and hurting customer trust.

- Overstocking — Keeping too much stock ties up cash, increases storage costs, and raises the risk of damage.

- Inaccurate Data — Manual entries often lead to mistakes, and those small errors snowball into major operational issues.

- Unpredictable Demand — Sudden changes in customer demand make planning difficult, unless you have a system that supports accurate forecasting.

- Complex Production Flow — With so many steps, machines, and teams involved, tracking everything manually becomes nearly impossible.

Core Features Every Manufacturing Inventory System Should Have

A strong manufacturing inventory system should support your entire production workflow from raw materials to finished goods. The best systems come with a set of features that help you streamline operations, reduce waste, and maintain full visibility over your inventory.

Real-time tracking gives your team instant visibility into every material—what you have, where it’s stored, and how quickly it’s being used. With continuous updates, you can prevent last-minute production delays, make faster decisions, and avoid second-guessing stock levels.

2. Production Planning and Scheduling

An efficient system helps you plan and schedule production based on demand, staffing, and machine availability. This minimizes downtime, improves workflow, and ensures your team starts and stops production at the right time. As a result, you produce more in less time and with fewer disruptions.

3. Bill of Materials (BOM) Management

BOM management ensures accuracy in every product you create. It clearly outlines the exact raw materials required for each item, helping your team avoid guesswork, prevent over-usage, and maintain consistency. With an accurate BOM, forecasting material needs also becomes much easier.

4. Material Requirement Planning (MRP)

MRP allows you to plan material purchases based on real demand rather than assumptions. It ensures you always have enough raw materials on hand without unnecessary overstocking. This helps reduce waste, improve cash flow, and keep your production cycles running smoothly.

5. Barcode or RFID Scanning

Barcode or RFID scanning speeds up receiving, storing, and material movement while minimizing manual errors. It makes tracking more accurate and effortless, especially in busy or large-scale production environments where precision is essential.

6. Automated Reordering

Automated reordering saves time and prevents disruptions by generating purchase orders the moment stock reaches a predefined level. It eliminates stockouts, reduces manual work, and keeps production running consistently.

7. Multi-Warehouse Management

For manufacturers operating multiple warehouses or production units, this feature provides a centralized view of inventory across all locations. It simplifies stock transfers, prevents imbalances, and improves fulfillment speed by ensuring the right materials are available where they’re needed.

8. Batch and Lot Tracking

Batch and lot tracking helps you trace materials and finished products back to their source. This is crucial for quality control, compliance, and handling recalls. It also boosts customer trust by improving transparency across the production process.

9. Quality Control Tracking

A strong system monitors product quality at every production stage. By identifying issues early, you reduce defects, minimize returns, and strengthen your brand reputation. Consistent quality tracking ensures every product delivered meets your standards.

10. Multi-Channel Syncing

If you also sell through eCommerce platforms or marketplaces, multi-channel syncing keeps your stock updated across all channels in real time. It prevents overselling, reduces order errors, and helps deliver a smooth customer experience.

Analytics turn your inventory data into meaningful insights. With detailed reports, you can identify trends, forecast demand more accurately, and make better operational decisions. Over time, improved visibility helps reduce costs and optimize production efficiency.

Benefits of Using a Manufacturing Inventory Management System

Businesses experience a wide range of improvements once they switch to a dedicated manufacturing inventory management system. Here are the core benefits:

- Accurate demand planning – You can forecast what materials you need and purchase them at the right time, reducing guesswork and preventing shortages.

- Real-time stock updates – Your team can see inventory changes as they happen, giving you complete visibility across every stage of production.

- Reduced waste and overstock – Better tracking helps you control storage, avoid piling up unnecessary materials, and cut down on waste.

- Faster production cycles – With the right materials always available, your production line moves smoothly without waiting for last-minute supplies.

- Traceability and compliance – Batch and lot tracking allow you to trace every product back to its source, ensuring quality and meeting regulatory standards.

- Automated purchase orders – The system creates purchase orders automatically when stock levels drop, preventing interruptions and saving time.

- Stronger supplier relationships – Automation and accurate data improve communication, reduce errors, and help you maintain consistent, reliable workflows with suppliers.

- Higher profitability – With less waste, fewer delays, and optimized operations, your business can increase output and improve profit margins.

Step-by-Step Guide: How to Implement a Manufacturing Inventory System

Implementing a manufacturing inventory system becomes much easier when you follow a structured roadmap. Here’s a simple step-by-step guide that helps you go from planning to full adoption without confusion or downtime.

1. Analyze Your Current Process

Start by reviewing how your inventory and production workflows currently operate. Look for mistakes, delays, or manual tasks that slow your team down. This gives you a clear picture of what needs improvement before introducing new software.

2. Identify Your Pain Points

Next, pinpoint the specific issues affecting your operations. It could be inconsistent stock counts, production delays, slow tracking, or difficulty forecasting materials. Understanding these pain points helps you focus on the features and solutions that matter most.

3. Choose the Right Software

Once you know your needs, select a system that’s easy to use, fast, and built for automation. Make sure it offers strong customer support, fits your production size, and integrates well with your existing tools. The right software should simplify your work, not make it harder.

4. Map Your Workflow

Before onboarding the system, outline how materials move through your factory—from procurement to production to storage. Mapping your workflow helps you configure the software correctly and ensures every step aligns with your actual operations.

5. Migrate Your Data

Gather your existing records, whether they’re in spreadsheets, ledgers, or other software, and move them into the new system. Clean, accurate data migration is essential to start strong and avoid errors that might affect production planning or stock visibility.

6. Train Your Team

A system is only effective when your team knows how to use it confidently. Provide hands-on training, simple guides, and ongoing support so everyone, from operators to managers, can navigate the software without hesitation.

7. Track KPIs and Improve Continuously

After implementation, monitor key performance indicators like stock accuracy, production speed, fulfillment time, and material waste. This helps you evaluate what’s working and where further optimization is needed. Over time, these insights will help you refine processes and boost efficiency.

Checklist for Choosing the Right Manufacturing Inventory

Best Practices for Manufacturing Inventory Management

To maintain efficiency and keep production running smoothly, here are the top practices manufacturers follow:

- Keep your BOM updated

Make sure every Bill of Materials reflects the latest product requirements so your team always uses the correct materials.

- Use ABC classification

Categorize inventory by value and importance so you can focus your attention on the items that impact your business the most.

- Run regular cycle counts

Count small portions of your inventory frequently instead of doing a massive yearly count. This keeps data accurate without disrupting operations.

- Standardize your production steps

Clear and consistent processes reduce errors, speed up training, and improve overall productivity.

- Automate wherever possible

Use automation for tasks like reordering, tracking, and data entry to minimize human error and save valuable time.

- Use safety stock wisely

Maintain the right amount of buffer stock to handle demand spikes without overstocking.

- Strengthen communication with suppliers

Transparent communication helps prevent delays, improves lead times, and builds stronger relationships.

- Align production with demand

Produce based on real demand forecasts to avoid bottlenecks, rushed orders, or excess inventory.

- Keep your warehouse clean and organized

A tidy, well-structured storage area speeds up picking, reduces mistakes, and supports smoother operations.

Efficiency Strategies & Techniques

- Just-in-Time (JIT)

Receive materials only when needed to reduce carrying costs and prevent unnecessary stock buildup.

- ABC Analysis

Prioritize inventory control by focusing on the small percentage of items that contribute the most value.

- Cycle Counting

Use this continuous auditing method to maintain accuracy year-round without shutting down production.

- Lean Manufacturing

Focus on reducing waste and using a “pull” system so production happens only when customer demand requires it.

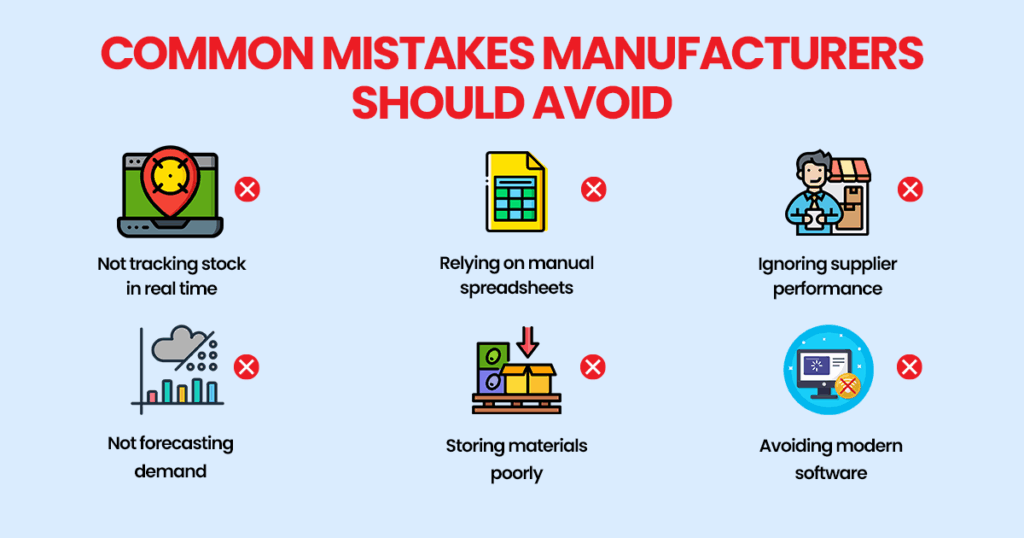

Common Mistakes Manufacturers Should Avoid

Many manufacturing issues come from poor inventory habits. Fixing these habits can save your business a lot of money. Avoid these mistakes:

- Not tracking stock in real time

- Relying on manual spreadsheets

- Ignoring supplier performance

- Not forecasting demand

- Storing materials poorly

- Avoiding modern software

How Inventory Software Reduces Production Costs

A good inventory management system doesn’t just track materials — it streamlines your entire production workflow. It helps you use resources more wisely, cuts unnecessary expenses, and keeps your operations running without chaos. When everything works in sync, your factory becomes faster, smarter, and far more cost-efficient.

- Prevents stockouts that stop production

- Avoids over-ordering materials

- Improves supplier coordination

- Reduces storage cost

- Minimizes human errors

- Predicts future demand

With fewer disruptions, you can produce more in less time and with less stress.

Industries That Benefit the Most

A manufacturing inventory system is useful across almost every production-based industry. Electronics manufacturers rely on it to track thousands of tiny components, while garment and textile companies use it to manage fast-moving materials and seasonal demand. Food and beverage businesses depend on precise tracking to maintain freshness and avoid spoilage, and pharmaceuticals need strict batch control for safety and compliance.

Automotive parts manufacturers use the system to handle complex assemblies, and furniture or woodwork companies benefit from better material planning and reduced waste. In short, any business that produces, stores, or assembles products can see major improvements with a manufacturing inventory system.

Why FullStro Is the Best Fit for Manufacturing Businesses

If you want a system that feels modern, powerful, and easy for your team, FullStro is built exactly for you. It gives you everything you need to manage raw materials, production, warehousing, and finished goods — all in one place.

FullStro helps manufacturers:

- Track multi-warehouse inventory

- Manage raw materials and WIP efficiently

- Get accurate reorder alerts

- Automate purchase orders

- Generate real-time reports

- Reduce waste and operating costs

- Improve production planning

It’s simple, fast, and perfect for growing manufacturers who want clarity, control, and higher profit.

Conclusion

A manufacturing inventory management system is more than a tool — it’s the foundation of a smooth and profitable production process. When inventory is managed well, your team works better, your costs go down, and your customers stay satisfied. It gives you confidence, predictability, and control over your entire production flow.

Whether you’re a small manufacturer or a fast-growing company, a modern inventory system helps you stay organized, work smarter, and scale without stress.

If you’re ready to improve your manufacturing process, now is the time to choose a system that supports your growth.